Lab Testing & Researching

- Tested By : PRI ASPHALT TECHNOLOGIES, INC.

- Tested date: 06 July, 2023

- Download Entire Lab Result: PDF

-

PRI ASPHALT TECHNOLOGIES, INC.

PRI is a national and global leader in materials testing and performance. PRI provides accredited, independent, third-party testing, evaluation, and technical services to the Asphalt/Bitumen, Building Materials, Chemical, Construction/Infrastructure, and Energy Markets.

2018 Original Test

In 2018, a series of rigorous tests were conducted to evaluate the performance and durability of our roofing solutions. These tests were designed to simulate real-world conditions and ensure that our products meet the highest standards of quality and reliability.

The results of these tests have been instrumental in refining our products and processes, allowing us to deliver superior roofing solutions to our customers. We continue to build on this foundation of excellence, driven by our commitment to innovation and customer satisfaction.

Flexibility Test

Much Improved flexibility

Flexibility, 23° was improved

(Failure to pass).

When installed new roof shingles have oil in the asphalt

that allows for daily expansion and contracting, which is

critical for performance and longevity.

Hail Impact Test

Hail Impact Resistance

Hail Impact was slightly improved after treatment. The improvement, 6.6%, was minimized by the type of shingle evaluated – organic felt based. The data suggests hail impact would have a greater improvement on FG mat-based shingles.

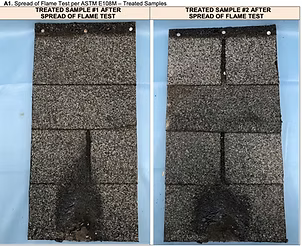

Fire Resistance Test

Inproved Fire Resistance

Fire Resistance ‘UL Speed of Flame:’ The treated shingles exhibited a flame spread of 86 in 2 vs. the untreated shingles exhibiting a 144 in2 spread. Greener Shingles rejuvenator proved 40% better flame resistance vs untreated shingles, this was unexpected.

Cedar Shingles Test

Additional Testing

We experimented on cedar shake shingles to test the effectiveness on a non-asphalt based shingle. After 3 weeks the moss and algae was smothered and washed off by rain and the color changed closer to what they where 44 years earlier when installed. We don’t promote rejuvenating cedar shake, but this experiment showed positive results. The Greener Shingles team is continually researching and developing to make our top selling product even better.

WHMIS Overview

WHMIS (Workplace Hazardous Materials Information System) is Canada’s standardized system for providing information about hazardous products used in workplaces. WHMIS includes:

- Labels: Provide essential hazard information on containers.

- Safety Data Sheets (SDS): Detailed documents outlining hazards, safe handling, and emergency procedures.

- Training and Education: Ensures workers know how to identify hazards and use products safely.

Ecoroof Atlantic WHMIS and Technical Details Content

Product Testing and Certification

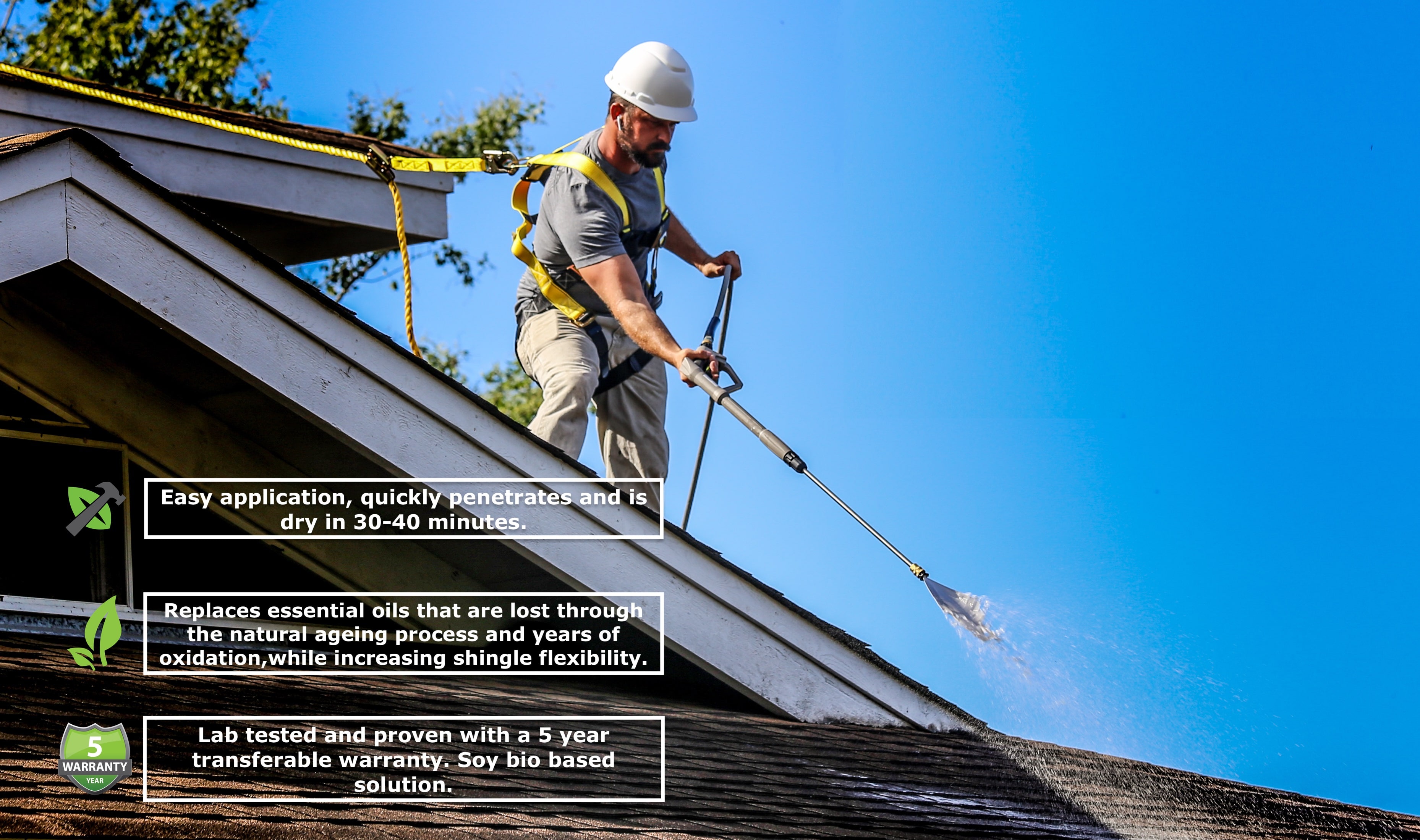

Ecoroof Atlantic uses Greener Shingles' asphalt shingle rejuvenation treatment. This eco-friendly solution extends the lifespan of roofs and reduces landfill waste. Testing highlights include:

- Improved Durability: Enhances flexibility, granular adhesion, and hail impact resistance.

- Fire Resistance: Demonstrated a 40% improvement.

- Environmental Benefits: Reduces the need for shingle replacement, minimizing waste.

Safety Compliance

The product complies with WHMIS requirements, ensuring it is safe for handling and use.

- Labels: Clear hazard symbols and handling instructions.

- Safety Data Sheets (SDS): Available for comprehensive safety guidelines.

By following WHMIS standards, Ecoroof Atlantic ensures safe application practices while promoting environmental sustainability. For more technical details, consult our Safety Data Sheet or contact our team.